Understanding the Correct Interpretation of Initial Pressure Drop for Pre-Filters

As environmental pollution continues to escalate, air quality has become a focal point of concern. The application of air filters has become increasingly common in areas such as construction, automobiles, and household appliances. Among these, the pre-filter, which plays a crucial role within air filtration systems, holds particular significance for beginners in its understanding of initial pressure drop. This article aims to dissect the accurate interpretation of initial pressure drop for pre-filters, offering insights from both theoretical and practical perspectives, along with practical recommendations.

I. The Role and Characteristics of Pre-Filters

A pre-filter is a filtration material positioned at the front end of an air filter, primarily used to capture larger particles and dust in the air. Its main function is to prevent pollutants from entering downstream systems and to safeguard the proper functioning of subsequent filters. Pre-filters are often made from synthetic fiber or glass fiber materials, offering high capture efficiency and low resistance.

II. The Meaning of Initial Pressure Drop for Pre-Filters

The initial pressure drop of a pre-filter refers to the pressure difference across the filter during the initial air circulation after installation. In the normal usage of a pre-filter, accumulation of particles gradually leads to filter clogging, resulting in an increase in pressure drop. Hence, the initial pressure drop of a pre-filter is a significant indicator for determining filter lifespan and replacement intervals.

III. The Correct Interpretation of Initial Pressure Drop for Pre-Filters

1. Theoretical Analysis:

The initial pressure drop of a pre-filter is influenced by factors such as filter type, size, material, and usage environment. Generally, the initial pressure drop of a pre-filter should be maintained within a reasonable range to ensure effective filtration while minimizing energy consumption. Therefore, when selecting and installing pre-filters, it is important to establish appropriate standards for initial pressure drop based on actual conditions.

2. Practical Experience:

To correctly interpret the initial pressure drop of pre-filters, beginners are advised to consider the following points:

- Regularly inspect and record the initial pressure drop to monitor filter performance.

- Replace pre-filters promptly based on pressure drop changes to prevent filter clogging and disruptions to normal operation.

- When cleaning filters, follow the manufacturer’s guidelines to avoid damaging the filter.

- When selecting pre-filters, choose the appropriate model and specifications based on specific air quality requirements and usage environment.

Pre-filters are a critical component of air filtration systems and play a vital role in maintaining air quality. A correct understanding of the meaning and approach to initial pressure drop for pre-filters is essential for beginners. By appropriately selecting, installing, and maintaining pre-filters, we can better safeguard indoor air quality and create a healthier living environment.

For beginners, mastering the correct interpretation of initial pressure drop for pre-filters is crucial. Only by accurately grasping their role and characteristics, and by establishing and maintaining the initial pressure drop appropriately, can we effectively ensure air quality and provide a favorable indoor environment. It is hoped that this article’s analysis and recommendations will aid beginners in better understanding and applying pre-filters.

Understanding the Impact of Airflow Resistance on Medium Efficiency Air Filters

In the field of air filtration, medium efficiency air filters play a crucial role in effectively removing particles and microorganisms from the air, thereby ensuring indoor air quality. However, a significant factor that cannot be overlooked is airflow resistance, which has a significant impact on the operation of medium efficiency air filters. This article will delve into the effects of airflow resistance on the operation of these filters and provide optimization recommendations.

1. What is Airflow Resistance for Medium Efficiency Air Filters?

Airflow resistance for medium efficiency air filters refers to the resistance generated by the filter when air is being filtered. As air passes through a medium efficiency air filter, the filter media intercepts and adsorbs particles from the air, resulting in cleaner air. However, the fineness of the filter media and its structural design can impede the flow of air, leading to airflow resistance.

2. Effects of Airflow Resistance on Filter Operation

a. Decreased Airflow: With increasing airflow resistance, the airflow through the medium efficiency air filter gradually decreases. This could lead to a reduction in indoor air purification efficiency and may even impact the overall air handling system.

b. Increased Energy Consumption: To overcome the resistance caused by airflow resistance, the air handling system may need to increase the fan power, thereby raising energy consumption costs.

c. Reduced Filter Lifespan: High airflow resistance can accelerate the wear and clogging of filter media, thus shortening the lifespan of medium efficiency air filters.

d. Higher Maintenance Costs: Due to filter clogging caused by airflow resistance, more frequent replacement of filter media may be necessary, resulting in increased maintenance costs.

3. How to Reduce Airflow Resistance for Medium Efficiency Air Filters

While airflow resistance is unavoidable, several measures can be taken to reduce it and enhance air filtration efficiency for medium efficiency air filters:

a. Regular Filter Replacement: Regularly replace the filter media in medium efficiency air filters to prevent excessive clogging, ensuring proper air circulation.

b. Use High-Efficiency Filter Media: Opt for high-efficiency filter media that can reduce airflow resistance while maintaining effective filtration.

c. Increase Filter Surface Area: Increasing the surface area of medium efficiency air filters disperses airflow resistance and slows down filter clogging.

d. Proper System Design: In the design of air handling systems, plan airflow paths and filter placements sensibly to minimize airflow resistance.

4. Conclusion

Medium efficiency air filters, as crucial air filtration devices, are affected by airflow resistance. Understanding the effects of airflow resistance on the operation of medium efficiency air filters can assist in optimizing filtration systems, enhancing air purification efficiency, and reducing operational costs. By regularly replacing filters, selecting high-efficiency filter media, increasing filter surface area, and designing systems thoughtfully, we can better ensure indoor air quality and create a healthy indoor environment.

Do you understand HEPA Filter?

The HEPA filter is an essential component of cleanrooms and ventilation systems.

The removal efficiency of HEPA filters is exceptionally high, especially for fine particles. They can effectively remove smoke, dust, and even contaminants like bacteria. As a result, they have a high market demand. Even particles as small as 0.3 micrometers in diameter cannot penetrate this type of filter.

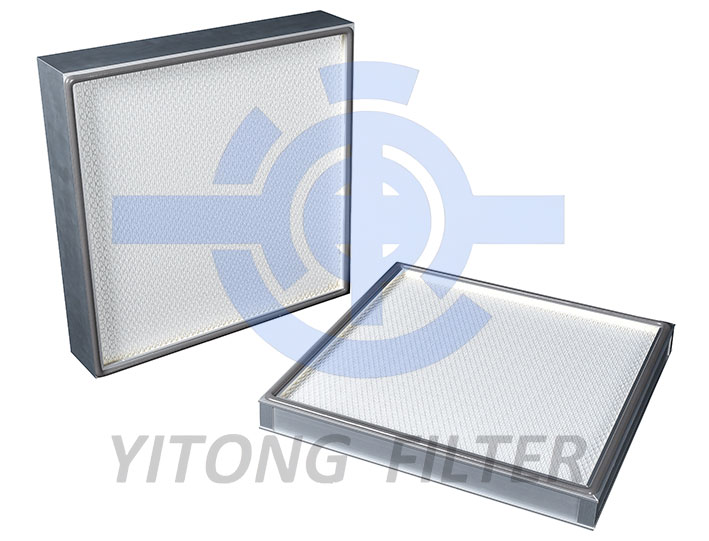

From a technical standpoint, HEPA filters come in different materials, including PP filter paper, glass fibers, and melt-blown polyester non-woven fabrics, among others. These different materials give rise to various manufacturing processes and result in large dust-holding capacities. These filters exhibit high overall filtration precision and can also be customized.

After receiving size and shape requirements from customers, manufacturers process and treat the filters accordingly to meet their specific needs. Currently, HEPA filters find applications in various environments, including operating rooms, animal facilities, crystal laboratories, and even aviation-related settings.

The technological features of HEPA filters are worth studying. They use seamless sealing technology to ensure excellent sealing effects, significantly prolonging their lifespan and virtually eliminating leakage issues. If one observes the filter material, they will notice the incorporation of metal mesh with varying thickness on both sides. Adjustments can be made based on the usage environment, and efficiency can be assessed using relevant industry standards as references.

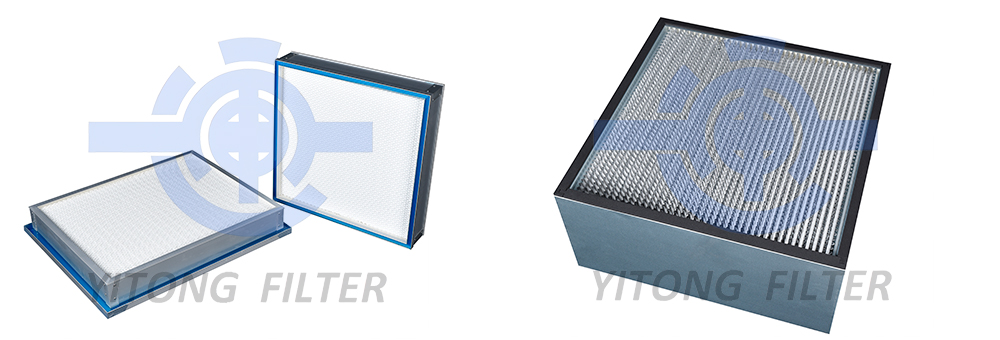

HEPA filters come in two common structural types: Mini-pleat and Separator.

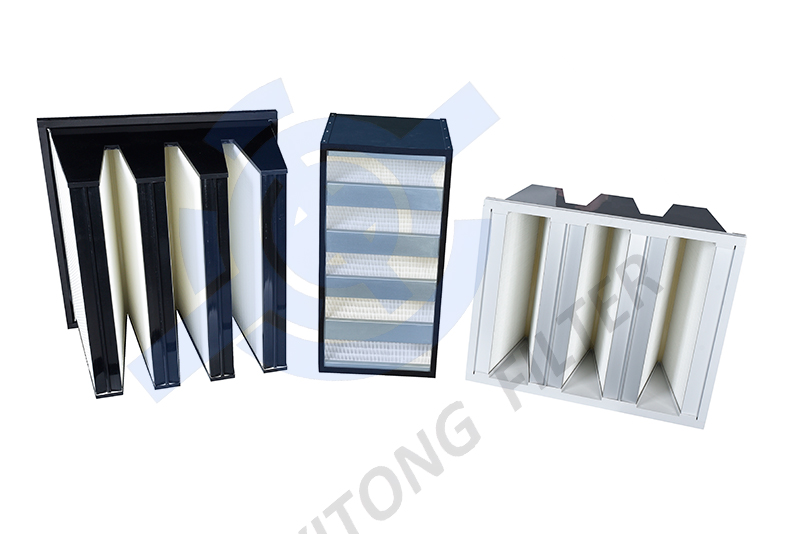

The Mini-pleat HEPA filter structure refers to the design where the HEPA filter's interior is divided into multiple small compartments with separators. Each compartment serves as an independent filtration unit. This structure effectively increases the filtration area and prevents the failure of one unit from affecting the entire filter's operation. Moreover, the Mini-pleat structure enhances the stability and lifespan of the filter. In practical applications, Mini-pleat HEPA filters are often used in places requiring high airflow and high filtration levels, such as cleanrooms and medical laboratories.

The Separator HEPA filter structure lacks the Mini-pleat design inside the HEPA filter. This structure is relatively simple and lacks the limitations of compartments, leading to a more uniform filtration effect. Additionally, Separator-structured filters are more suitable for handling lower air volumes. Consequently, in settings where low resistance and moderate to low airflow are needed, like ventilation and air conditioning systems and electronics factories, Separator-structured HEPA filters are more common.

Considering these two different HEPA filter structures, the Mini-pleat structure suits places requiring high airflow and high filtration levels, while the Separator structure is more appropriate for medium to low airflow settings. Selecting the appropriate structure type ensures that HEPA filters deliver optimal filtration efficiency and performance in various application environments.

The Mini-pleat and Separator structures of HEPA filters have certain design and application differences. Understanding these distinctions can help us make better choices and use HEPA filters effectively, enhancing the filtration efficiency and air quality of cleanrooms and ventilation systems.

If you'd like to learn more about HEPA filters, feel free to contact us anytime. We'll provide answers and services to meet your needs.

Guidelines for Measuring Initial Resistance of Pre-Filters and Medium-Efficiency Filters

Pre-Filters and medium-efficiency filters refer to a type of high-performance air filter that effectively removes particles and pollutants from the air, maintaining indoor air cleanliness and health. During the usage of these filters, it's essential to understand and determine their initial resistance to ensure their proper functioning and long-term effectiveness. This article will provide a detailed introduction to the measurement methods of initial resistance for Pre-Filters and medium-efficiency filters, aiming to offer you some insights.

Significance of Initial Resistance for Pre-Filters and Medium-Efficiency Filters

The initial resistance of these filters refers to the resistance value measured right after the installation of the filter. It directly impacts the filter's lifespan and filtration efficiency. By measuring the initial resistance, we can promptly assess whether the filter needs replacement or cleaning, ensuring it remains in good working condition. Therefore, understanding and determining the initial resistance of Pre-Filters and medium-efficiency filters are crucial.

Measurement Methods for Initial Resistance of Pre-Filters and Medium-Efficiency Filters

1. Preparation: Firstly, you need to prepare a tool for measuring initial resistance, such as a specialized filter resistance measurement device. Additionally, ensure that the filter being tested is properly installed and connected, with no air leakage or other faults.

2. Measurement Process: Connect the pressure sensor or measurement head of the filter resistance measurement device to the inlet and outlet of the filter, ensuring a proper seal. Then, start the filter resistance measurement device and record the displayed initial resistance value.

3. Data Analysis: Based on the recorded initial resistance value, further data analysis can be conducted. Typically, the initial resistance of Pre-Filters and medium-efficiency filters should fall within a certain range. If the initial resistance exceeds the normal range, it's necessary to consider replacing or cleaning the filter.

Additional Considerations

1. Regular Measurement: To ensure the proper operation of Pre-Filters and medium-efficiency filters, it's recommended to regularly measure the initial resistance, generally every three months. If abnormal resistance increase is detected during measurement, appropriate actions should be taken promptly.

2. Proper Installation: When installing Pre-Filters and medium-efficiency filters, ensure that the inlet and outlet of the filter are securely connected to the ventilation system, with no air leakage. Additionally, avoid blocking the inlet and outlet of the filter to prevent interference with initial resistance measurement and normal air filtration efficiency.

Determining the initial resistance of Pre-Filters and medium-efficiency filters is a crucial step in ensuring their proper functioning. Through correct measurement methods and regular monitoring, we can promptly understand the filter's operational status and take appropriate measures to ensure its long-term performance. We hope that the provided guidelines for measuring initial resistance of Pre-Filters and medium-efficiency filters will be helpful to you, enabling you to better understand and manage the use and maintenance of these filters.

Introduction to HEPA Filter Characteristics

In general, laminar flow refers to the layering of indoor air. Efficient air filters, such as those used in cleanrooms, allow dust particles to move within this laminar flow. This means that dust particles are carried by the air. In cleanrooms and controlled environments within air conditioning systems, efficient air filters create a non-laminar flow, meaning that suspended particles in the air can quickly mix, stationary particles indoors can become airborne again, and some air might become stagnant.

How Effective is the Use of HEPA Filters?

HEPA filters primarily control bacteria and viruses. Microorganisms primarily attach to dust particles. By effectively controlling airborne dust particles, HEPA filters also control bacteria and viruses in the air. To achieve this, particle-blocking HEPA filters must be used for filtration. Generally, standard HEPA filters can achieve a filtering efficiency of up to 99.996% for bacteria, which essentially meets the requirements for filtration and purification in a biological cleanroom.

The main filtration principle of HEPA filters is based on the principle of inertia. Larger particles are filtered out but can accumulate and block the HEPA filter, reducing its lifespan. To counteract this, special construction and filter materials are used to give the filter a self-cleaning function. Large particles cannot adhere to the HEPA filter, ensuring that filtering efficiency is not compromised and extending the filter's lifespan.

What are the Product Characteristics of HEPA Filters?

1. HEPA filters can be categorized into on their structure: Mini-pleat HEPA Filter and Separator HEPA Filter

2. The outer frame of HEPA filters can be made from galvanized steel, aluminum alloy, or stainless steel, offering users various material choices.

3. HEPA filters can be classified into ordinary, high-temperature resistant, and humidity-resistant types based on their characteristics.

4. HEPA filters are known for their high filtration efficiency, low resistance, and high dust holding capacity.

HEPA filters use ultra-fine glass fiber paper as the filtration material and pleated paper as partitions. These components are assembled within the frame. They are applied in various purification and supply air systems, clean laminar flow hoods, clean workbenches, and air purifiers to achieve air cleanliness standards.

How to Determine When to Replace the Primary Efficiency Air Filter?

An air filter is an essential component used to protect workshops and HVAC systems. In clean rooms and ventilated air conditioning systems, the primary efficiency air filter plays a role in filtering out dust and particles from the air. Over time, the filter will gradually accumulate dust and block airflow. Therefore, regular inspection and replacement of the primary efficiency filter are particularly necessary.

To help everyone determine whether the primary efficiency filter needs replacement, we have compiled some simple and practical methods for inspection, as follows:

1. Visual Inspection:

Firstly, we can visually inspect the condition of the primary efficiency filter. Open the filter cover and carefully observe whether there is a significant accumulation of dust and particles on the filter surface. If the filter is visibly blocked, it indicates the need for replacement.

2. Pressure Differential Test:

When the primary efficiency filter is in normal operation, it will present a certain level of resistance. Pressure differential is a measure of the resistance. Use a pressure gauge to measure the pressure difference between the inlet and outlet of the primary efficiency filter. If the pressure difference exceeds the maximum allowable value specified by the manufacturer, it is time to replace the filter.

3. Dust Particle Detection:

Utilize a dust particle counter or laser particle counter to measure the quantity of dust particles inside the primary efficiency filter. According to equipment requirements, if the particle counter detects a quantity of particles exceeding a certain standard, it indicates that the primary efficiency filter needs replacement.

4. Anemometer Inspection:

An anemometer is a specialized testing device that can measure air velocity and pressure differential. By using an anemometer to measure changes in air velocity and pressure differential of the primary efficiency filter, one can assess the filter's resistance condition. If resistance significantly increases, it indicates that the primary efficiency filter requires replacement.

By employing these simple and practical inspection methods for the primary efficiency air filter, we can determine whether it needs replacement. Regularly monitoring the status of the filter and replacing it in a timely manner ensures the normal operation of workshops and HVAC systems, providing clean and healthy air.

Air filters, especially primary efficiency filters, play a crucial role in maintaining clean rooms and ventilated air conditioning. Damage to these filters can directly impact the subsequent stages involving Medium Filters and HEPA Filters. Hence, regular inspection and replacement of filters are of utmost importance. Hopefully, the aforementioned simple inspection methods can assist everyone in creating cleaner workshop environments and fresher air!